EMP Rotomoulding

EMP Rotomoulding, a forward-looking company

Rotomoulding, EMP’s DNA

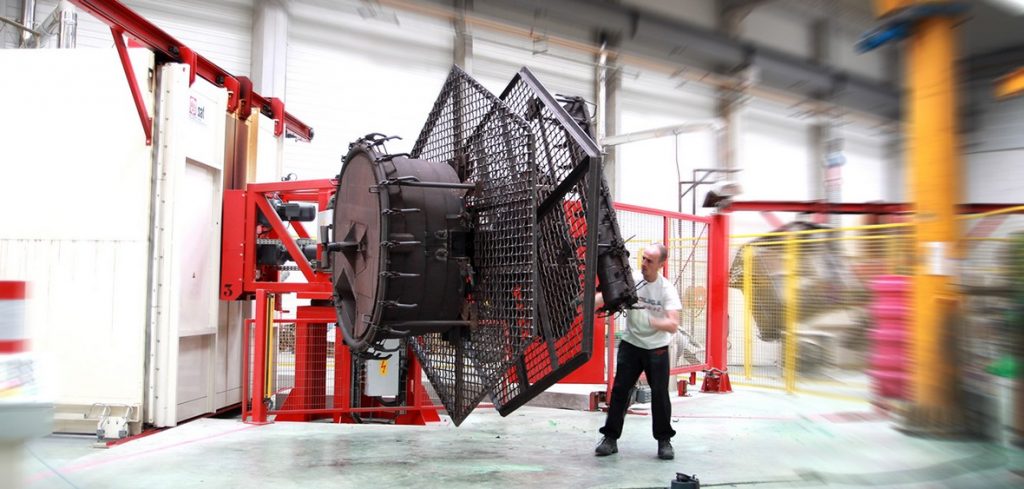

Rotomoulding is a process of transformation of plastics, used to make hollow parts of small or large dimensions with variable geometries, from the simplest to the most complex form.

Emp’s proven process is highly adaptable as it allows the integration of handles, nameplates, inserts and logos without welding and fitting operations. Likewise, it makes possible the varied and infinite shapes and offers a large choice of colors, imitation stone, rough or polished appearance. The material is treated to resist ultraviolet, it is insensitive to corrosion, compatible with food and retains its mechanical properties from -30 ° C to + 60 ° C.

Fully recyclable, it is resistant to chemical attacks and shocks.

EMP has the particularity of manufacturing monobloc hollow bodies from 1 to 20,000 liters.

EMP EXPERTISE

For more than 30 years, EMP has acquired know-how on all rotational molding techniques. At EMP, the integrated design office, combined with a product designer and the boilermaking workshop that manufactures the tools, gives the company great latitude and allows it

to promote tailor-made products at each stage of its process.

The molds are imagined, digitized and then designed within the factory. After the study, the design and the realization of the tools, the rotational molding of the parts is done on the same site.

Thanks to its mastery of the process from A to Z, EMP can complete, improve or modify a part on demand. The design office, equipped with Solidworks and a 3D printer, ensures the feasibility of the products and creates their materialized “3D reflection” images and 3D models.

INNOVATIVE TECHNICAL ASSETS

From the design of its products, EMP integrates technical elements that make the difference in their daily use. The quality and guarantee of French manufacturing EMP ensure that the products produced are highly resistant and have an exceptional longevity.

Thanks to its mastery of rotational molding, EMP develops an infinite range of parts. The company designs, manufactures and creates custom-made molds for the rotational molding of parts of all volumes. EMP also manufactures its own ranges (equestrian, breeding, environment, street furniture, rainwater harvesting).

MAJOR PLAYER IN ROTATIONAL MOLDING

Represented in more than 10 European countries, overseas and on the African continent, EMP manufactures an infinite range of polyethylene retention containers. Thus, more than 125,000 pieces leave the Breton factory each year.

A true designer of parts with value-added accessories, EMP now has all the know-how to support its customers in France and throughout Europe.

MADE IN FRANCE

The entire “Product in France” chain is mastered, from the design in the design office to the output of the parts in the workshop. The EMP production unit, located on a site of more than 2 ha with a building of 6,500 m², near Saint-Malo, is one of the most modern and innovative factories in France.

TEAMS & EQUIPMENT

THE TEAMS

• Expert employees

• Mastery of trades

• Responsiveness and flexibility

• A responsive

design office• A “Product Design” department

THE EQUIPMENT S

• A boilermaking workshop

• A micronization

unit• A fast

mixing unit• An assembly

workshop• A 3D printing unit

THE MACHINE PARK

• 5 Armour-type ovens with 3 arms

diameters: ø 2600 mm (x 2), ø 3000 mm, ø 3500 mm, ø 4000 mm.

• 1 carousel type oven with 2 arms in diameter: ø 5000 mm.

INTEGRATED BOILERMAKING WORKSHOP

EMP, the only fully integrated French manufacturer!

EMP designs its products and manufactures them from A to Z: design at the design office, mold manufacturing and rotational molding of plastic parts, then assembly and finishing of products.

Thanks to its boilermaking workshop composed of 6 people, EMP is completely autonomous for the manufacture and maintenance of its molds.